Cannes Lions

Piñatex

L&C, New York / DOLE SUNSHINE COMPANY + ANANAS ANAM / 2022

Overview

Entries

Credits

Overview

Background

According to the United Nations Industrial Development Organization Next to the oil industry, leather is one of the most polluting production sectors in the world.

Every year over 2.5 million tons of pineapple are grown in the Philippines.

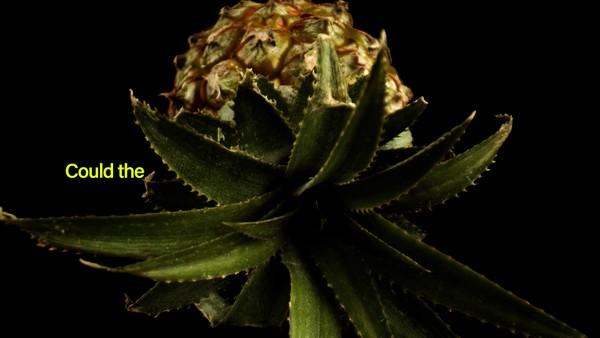

While the fruit is packaged to feed people all over the world, pineapple leaves are left behind. For every ton of pineapples harvested, 3 tons of leaves are wasted. And when left to rot could create methane emissions over 20 times more harmful than CO2. Could the green answer to leather be found on pineapple leaves?

To make a change. Dole, one of the largest producers of pineapples in the world, partnered with Ananas Anam to produce Piñatex. A vegan, cruelty-free and sustainable leather alternative; made from the fiber of pineapple leaves that would otherwise go to waste.

Idea

Dole, one of the largest producers of pineapples in the world, partnered with Ananas Anam to produce Piñatex: A vegan, cruelty-free and sustainable leather alternative; made from the fiber of pineapple leaves that would otherwise go to waste. There is no need for extra land, water or land to grow it. In the past, the leaves have been left to rot or they have been burnt. By valorizing the pineapple harvesting, we have saved 825 tons of leaves to be burnt, and therefore saved 264 CO2 eq tons to be released into the atmosphere a year. No hazardous chemicals used in production.

Closed loop production – residual leaf biomass is used as natural fertilizer/biofuel.

Non-woven mesh is biodegradable.

Strategy

The main strategy was to convince fashion brands to start using Piñatex instead of animal leather which production causes enormous hazard to our planet. And we achieved it surpassing our expectations.

Execution

There is no need for extra land, water or land to grow Pinatex. In the past, the leaves have been left to rot or they have been burnt. By valorizing the pineapple harvesting, we have saved 825 tons of leaves to be burnt, and therefore saved 264 CO2 eq tons to be released into the atmosphere a year. No hazardous chemicals used in production. Closed loop production – residual leaf biomass is used as natural fertilizer/biofuel. Non-woven mesh is biodegradable.

Outcome

Pinatex brings socio-economic stability in the rural areas of the Philippines. It provides job security and diversifies income streams. At the farming level jobs have been created in multiple areas; leaf gathering, fibers extraction, logistics and quality control systems. Furthermore, our business model is unlocking commercial potential for natural fibers in developing countries: strengthening global value chains for rural development, poverty alleviation and the environment. Piñatex has raised awareness for natural pineapple leaf fibers from the government to industry and research. Over 200 brands in more than 80 countries are now using Piñatex to become more sustainable. Including Hugo Boss, H&M and Nike who use Piñatex to create their happy pineapple sneaker collection, made of Dole pineapple leaves that would otherwise go to waste.Piñatex® is part of Dole's ongoing efforts to achieve zero waste from its farms by 2025. By upcycling waste, we are creating change beyond the food industry.