Innovation > Innovation

SHARED SAFETY. A FULLY PARTICIPATORY CONSTRUCTION MANAGEMENT PLATFORM

RE-BE, Seoul / HOBAN CONSTRUCTION LTD X PLUXITY / 2022

Overview

Credits

Overview

Why is this work relevant for Innovation?

Existing construction management platforms require language competence and tech literacy. Such solutions leave out the millions of migrant workers worldwide who are confronted by the language barrier every day.

Shared Safety changes this by enabling seamless, barrier-free communication between all participants in a construction project. From top-level planners to migrant construction workers, the most neglected and vulnerable group among all workers, everyone has access to the same information in real-time.

All workers, regardless of background, language competence or tech literacy, are empowered to effectively participate in the construction process making sites safer and more inclusive.

Background

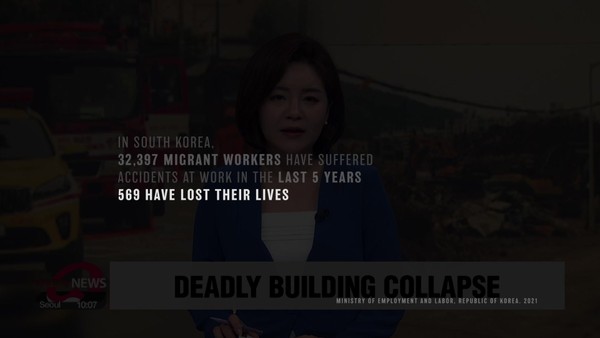

According to ILO, a quarter of a billion people work in the global construction industry. A significant percentage are migrant construction workers. Even as clear communication is essential to worker safety in the changeable environment of a construction site, millions of migrant workers around the world have no choice but to communicate in an unfamiliar language on a daily basis.

Existing platforms require language competence and tech literacy, excluding migrant workers by design. As a result, they remain at a far greater risk of injury and death than their local peers.

Pluxity, a South Korea tech startup, decided to leverage its bespoke digital twin technology by partnering up with Hoban Construction, one of South Korea's largest construction companies to create a new platform for construction management. The result of the collaboration is Shared Safety.

Describe the idea

Clear communication is essential to safety on ever-changing construction sites where the smallest confusion can cause serious harm. Accidents occur when planners, site managers and construction workers do not have the same information available to them.

Shared Safety's digital twin technology allows everyone involved in the construction process to view the same information in real-time. This information is automatically adapted to the needs and requirements of each group. Top-level planners use the digital twin's powerful AI modeling capabilities and scheduling features to plan effectively. On-site managers use the platform to monitor site conditions. Workers receive hazard alerts in the form of animated pictograms on their smartbands. They acknowledge the alerts and updates by tapping on their smartbands allowing them to respond to necessary updates in real-time.

What were the key dates in the development process?

Development Timeline

- February 2020: Development Begins

- October 2020: Prototype Development

- June 2021: Architectural Engineering + Digital Twin + Visualization Service Convergence (TAD)

- February 2022: Prototype Testing

- April 2022: User Field Test

- August 2022: Service Launch

Describe the innovation / technology

Shared Safety automatically adapts site information to the requirements of each user group. From top-level planners to on-site construction workers, everyone is able to view the most up-to-date information in real-time.

The service flow of Shared Safety involves 4 processes that are active at all times.

Prediction:

Powerful AI modeling system provides accurate projections based on site data collected in real-time.

Planning:

Project planners use projections to effectively plan and distribute resources in the safest way possible.

Feed:

On-site managers issue alerts when risks are identified.

Feedback:

Workers use smartbands to receive and respond to animated pictogram alerts.

These smartbands are reprogrammed off-the-shelf smart watches that are integrated into the Shared Safety platform, enabling them to receive alerts anywhere on the construction site.

Development Ecosystem

- Platform: AWS (Amazon Web Services) based on SaaS (software as a service)

- Device OS: iOS & Android

- 3D Engine: WebGL based on proprietary engine

- 3D Model Data: IFC, CityGML, FBX.

Key Development Stages

- Web-based 3D visualization

- Risk Factor Assessment Model (capable of calculating 8 different risks)

- Service UI Design Development

Describe the expectations / outcome

Select implementations of Pluxity's Digital Twin:

- Incheon Airport

- Samsung Display Factory in Tangjeong

- Seoul Subway System (Line 2)

Total investment received for Digital Twin development:

4,000,000,000 KRW (approx. 3.2 million USD)

Expected Benefits of Shared Safety, Digital Twin for Construction Management

1. Safety

- Increased participation of migrant workers in safety eduction due to visual aids (3D visualizations, Pictograms).

- Improved risk projections through use of real-time data with 3D visualizations.

2. Productivity

- AI-based risk assessment automation.

- Improved collaboration and communication between participants thanks to visual aids such as 3D visualizations.

- Improved bid competitiveness of construction companies.

3. Innovation

- Web-based BIM with real-time data and 3D visualization. A more inclusive, easier to use, and significantly cheaper than other professional BIM solutions.

- Workers able use platform using any smart device.

- Open API-based platform that accommodates new technologies.

More Entries from Early Stage Technology in Innovation

24 items

More Entries from RE-BE

3 items