Innovation > Innovation

VEHICLE OF CHANGE

NORD DDB, Stockholm / VATTENFALL / 2023

Overview

Credits

Overview

Why is this work relevant for Innovation?

This brief is taking on one of the biggest challenges of our time: how do we get the automotive industry, with its huge power and influence, to go fossil free? To do that we need to be truly innovative.

We’re innovating creatively by producing not a campaign but a product, and open sourcing the data behind it for anyone to use. Because the world doesn’t need more advertising talking about climate change. It needs real change.

We’re innovating technically by doing something that’s never been done – developing the first vehicle made without fossil fuels in its entire production chain.

Background

We’re staring a climate emergency in the face. Only systemic transformation can deliver the huge cuts in global CO2 emissions we need. According to the UN, transport accounts for a quarter of those emissions.

Leading European energy company Vattenfall has been on a mission to remove fossil fuels from all parts of society since 2018. They already supply fossil free energy to consumers and businesses, and have one of Europe’s largest electric vehicle charging networks.

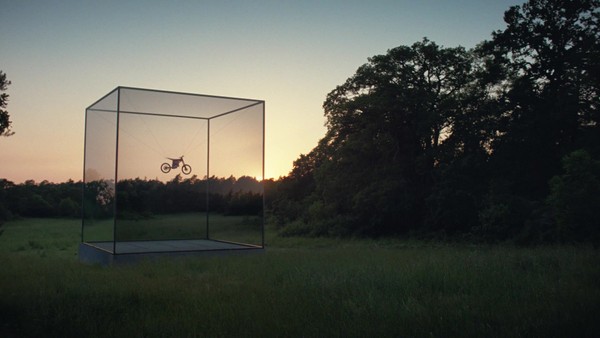

Swedish electric motorcycle producer CAKE was set up in 2018 with a purpose to inspire the shift to a zero-emission society, combining excitement with responsibility.

Both organisations recognise that the only way to achieve this huge systemic transformation is to collaborate beyond traditional industry borders, because a fossil free future isn’t possible without transforming high-emitting industries. None more so than the automotive industry, which Vattenfall has identified as one of the biggest challenges to decarbonise.

Describe the idea

The world doesn’t need more advertising talking about climate change. It needs real change.

So when Vattenfall asked us to inspire the automotive industry to change by showcasing their expertise in decarbonising production chains, we proposed more than a campaign, we proposed a product. We recommended partnering with CAKE to create the first vehicle produced without fossil fuels.

Because, while EVs don’t emit CO2 when used, they create emissions when manufactured, assembled and transported. These can be 70% higher than petrol models.

Our objective isn’t just to decarbonise the production chain of one bike, but to inspire the entire automotive industry to do the same and go fossil free.

To create change at this scale, we’re turning competitive thinking and company secrets on their head for the climate, and instead we’re open-sourcing all the data from the project.

This is “one bike built to change how all vehicles are made”.

What were the key dates in the development process?

• Vattenfall and CAKE sign Letter of intent to collaborate: July 2021

• Results of Life Cycle Assessment of all the components of the CAKE Kalk OR bike: April 2022

• Full carbon footprint of the bike is published: August 2022

• Project is picked up and shared by World Economic Forum, Volkswagen and Polestar: August 2022

• Öhlins joins project: November 2022

• SKF joins project: April 2023

• Material testing (Papershell): ongoing

• Hydro joins project: June 2023

• First products in market: 2025

Describe the innovation / technology

We’re rethinking every step of the supply chain of the CAKE Kalk OR bike, by tracking emissions all the way to their source and developing solutions to remove them. We’re focused on tackling the root cause of emissions not compensating for them, so we don’t allow carbon offsetting.

The first action was to disassemble the bike, resulting in over 100 components made up of 2000 smaller parts. We then conducted a full Life Cycle Assessment (LCA) on every single part, mapping the highly complex supply chains and evaluating each individual carbon footprint.

This gave us a total carbon footprint for the bike of 1,186 kg CO2e, taking into account all materials processed, waste generated, energy and chemicals used and every kilometre of transport involved.

We’re now in the research and development phase, working with our partners to develop the cleanest solutions. And of course sharing all innovations for them to use more widely.

One key learning from the LCA was to focus on materials rather than individual components. For aluminium, the bike’s biggest material, we’re now testing fossil free options such as bringing production close to home, replacing some parts with fossil free steel or even using carbon-free paper-based replacements.

Describe the expectations / outcome

The project is inspiring change across the industry. We have seven new partners on board, from sustainable start-ups to world leading brands.

Öhlins, the leading suspension manufacturer who provide over 3 million components annually to Ferrari, BMW and Volkswagen, said “We supply some of the world’s top car brands. This project is the perfect opportunity for us to future-proof our suspension.”

PaperShell, who manufacture carbon-free materials, said “This has made the automotive industry aware of our plastic replacement, resulting in no less than 20 new enquiries.” This includes discussions with Polestar about removing plastics from the 51,000 EVs they sell annually.

And global bearing manufacturer SKF are using innovations from this project to reduce emissions across all their two-wheeler products.

The potential reach of collaborations like these is huge, not just for one bike, but for the industry. We’re only part way through our journey but already far exceeding expectations.

More Entries from Scalable Innovation in Innovation

24 items

More Entries from NORD DDB

24 items